Silicone casting journey: the beginning

One thing you need for RC vehicles are rubber tyres. Plastic ones just don’t cut in terms of grip, traction and realism in general.

There are some DIY options of doing it:

-

3D print tyres in flexible resin. That resin is not flexible enough though, and surface hardness is too far from ideal tyre rubber (60-70A vs 20-30A hardness).

-

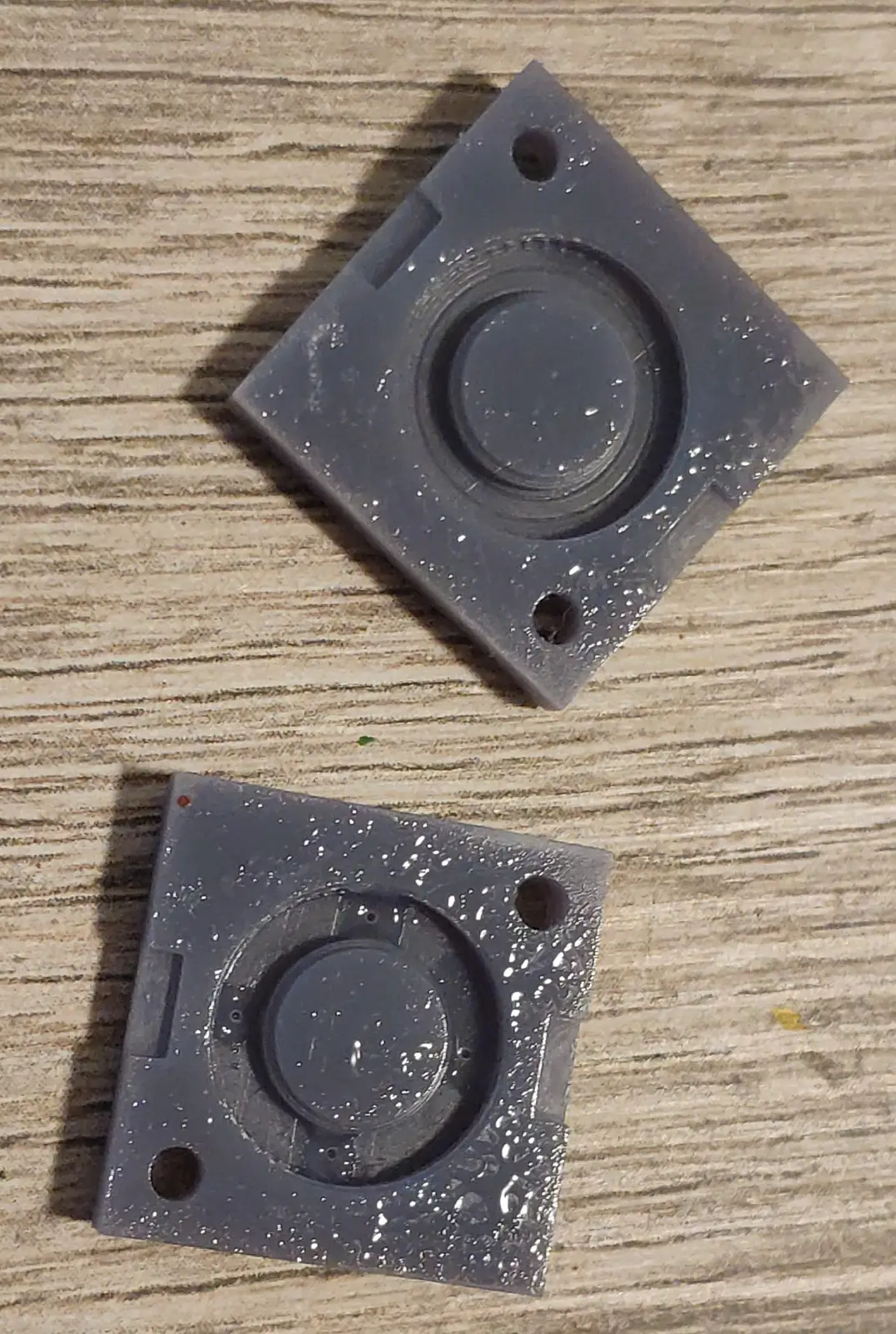

Cast silicone into 3D-printed resin mold. Silicone needs to be colored black and of particular hardness.

-

Case polyurethane rubber into silicone mold made from 3D-printed resin tyre. Silicone can be whatever suitable, polyurethane needs to be colored and of particular hardness.

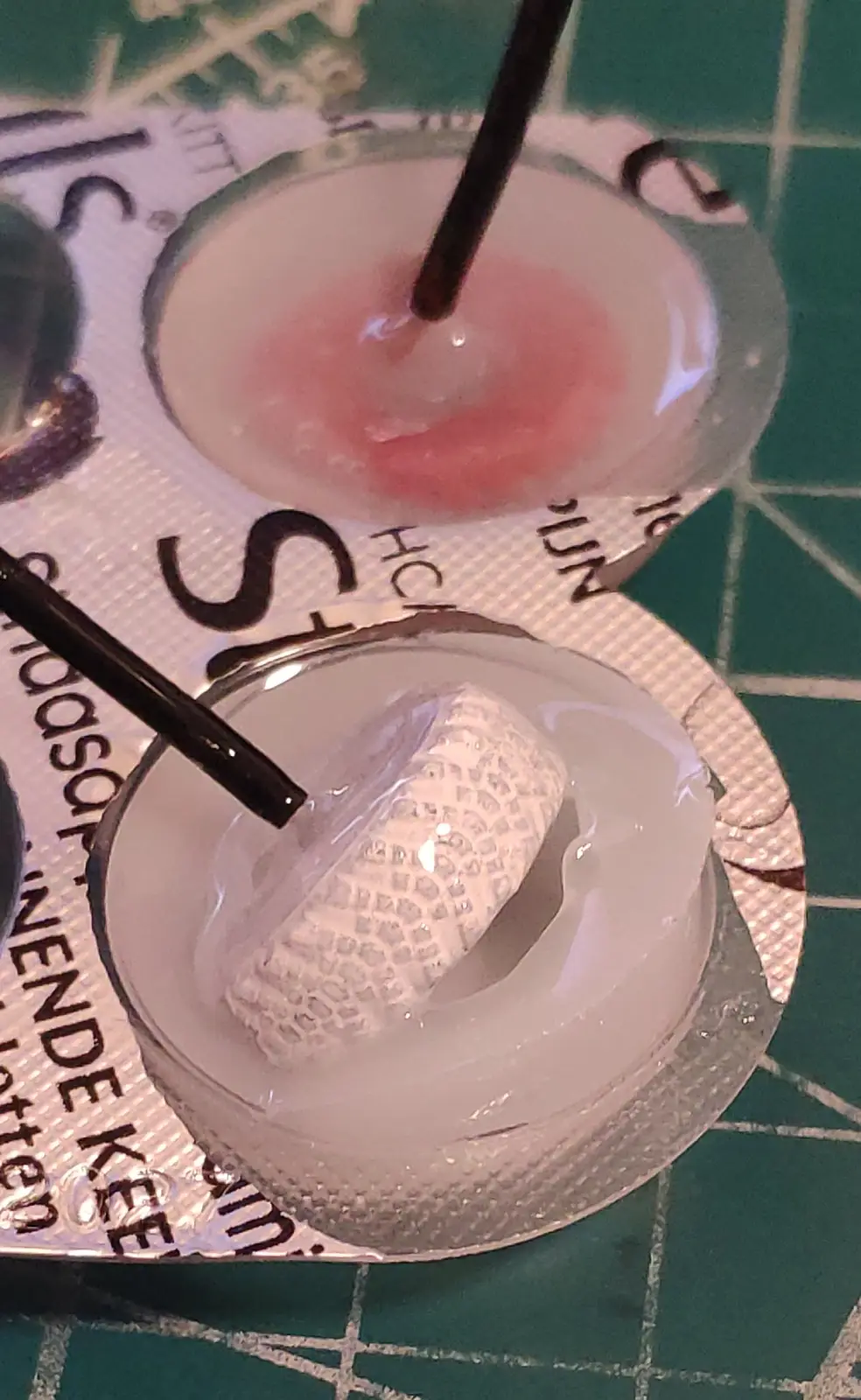

Liquid silicone comes as a 2 component mix and can be of 2 types: tin-cured and platinum-cured.

-

Platinum cured silicone is usually mixed in 1:1 ratio, is white-ish, does not shrinkage that much, and prevalent on AliExpress. The biggest downside bordering on deal-breaker is that a huge variety of substances inhibit platinum silicone curing, and those include photopolymer resin photoinitiator (which is phosphor-based). Inhibited, or poisoned, silicone will never cure and will remain gooey forever. It also changes its sticking properties and is very hard to remove (while cured silicone will not stick to anything except itself).

-

Tin-cured silicone is close to 10:1 ratio, worse shrinkage and durability, but does not get inhibited nearly as much. So it should be the preferred option when dealing with resin printed parts that don’t get abused a lot. The downside is that there are zero offers of it on AliExpress and Amazon.

I bought a small amount of platinum-cured silicone from Aliexpress, and made several failed attempts at casting resin-printed parts.

There are advices on the Internet (see below) of removing the residue photoinitiator from the 3D print, they consist of: curing the part in water, leaving the part in water for a long time, heat-treating the part, washing the part thoroughly.

Also there are some photopolymer resins that have different photoinitiator (Sirayatech Fast Smokey Black and Sirayatech Fast Navy Grey, to name some), which I plan to try in the future.

Further reading: https://blog.honzamrazek.cz/2022/07/preventing-platinum-cure-silicone-cure-inhibition-in-resin-printed-molds/ - an article from a very experienced person about curing inhibition and ideas to combat it.

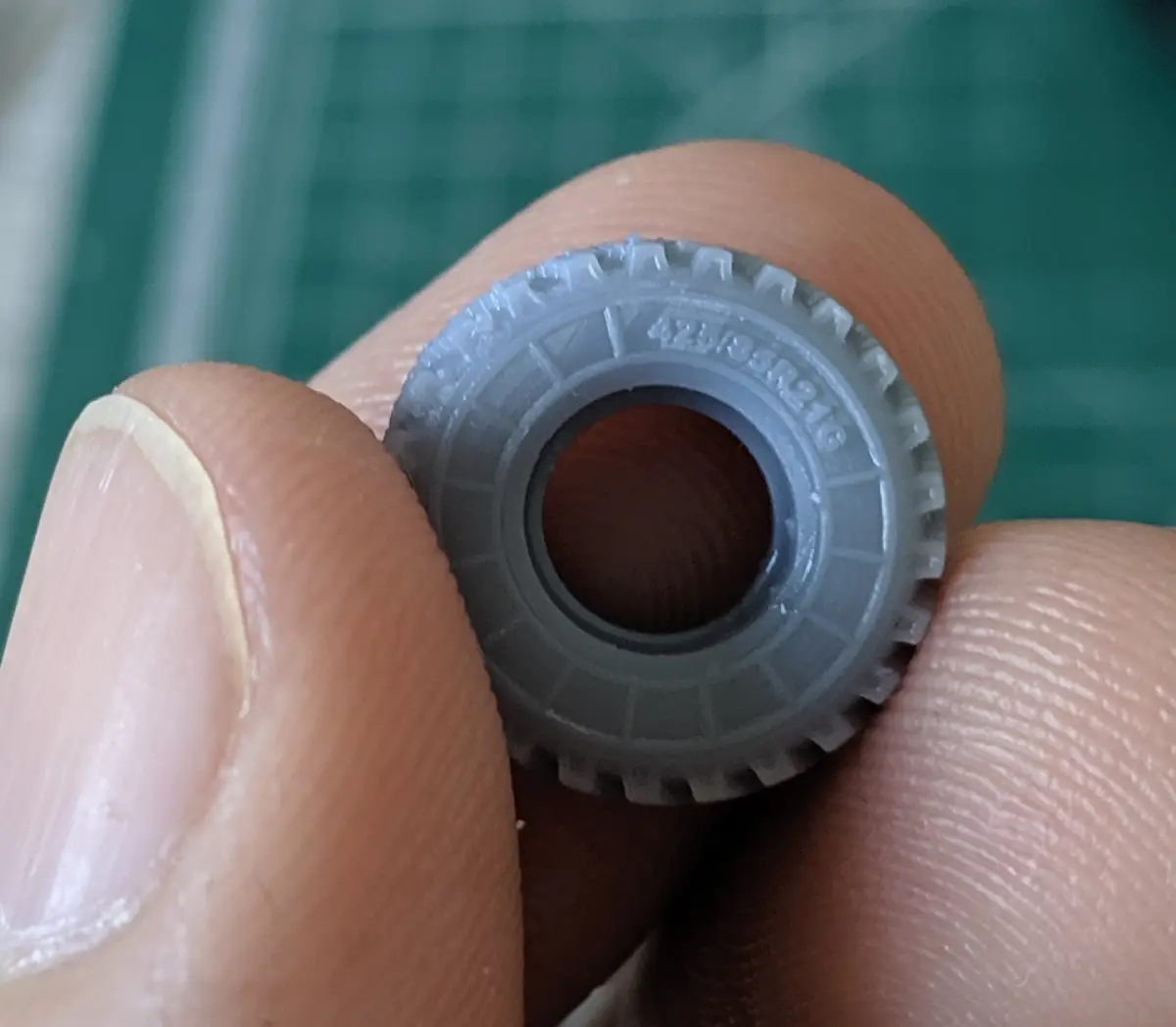

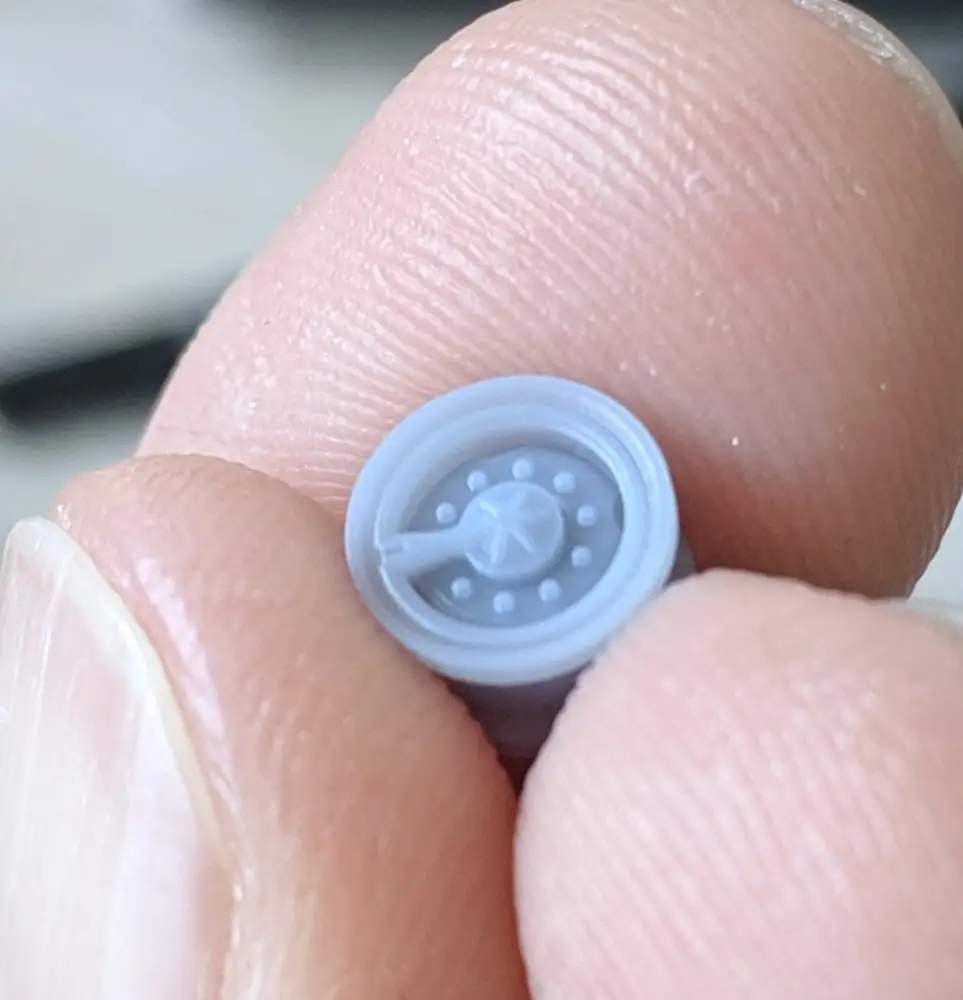

P.S. I am regularly surprised at how small the details can go on a resin-printed part. Here is a numeric designation on a tyre that is ~12mm large. Before, I didn’t make the details smaller than 0.15mm, but here some parts of text are smaller. There seems to some over-exposure though. And photo of the wheel rim just because it looks good.