Rare case of useful DIY, featuring laser engraver

So, during these winter holidays I got myself a laser engraver, and one thing I’ve wanted to try is engraving metal. The laser machine is TwoTrees TTS-10 Pro with a dual laser diode setup (2 5W diodes shining into one spot using mirrors), and I saw reviews where it can engrave metal.

| TwoTrees has a dedicated EU webshop and it’s ~100EUR cheaper to buy the machine there than from Aliexpress. I wish I found that before I ordered it. Aliexpress shop also ships from Germany, not from China, so it’s fast provided DHL is not celebrating Christmas. But due to broken aliexpress deadlines by a couple weeks, the seller sent a honeycomb table for free, so still a good purchase. |

Finally this weekend I found time to try this and do a useful job of engraving a steel metal dog tag for my dog.

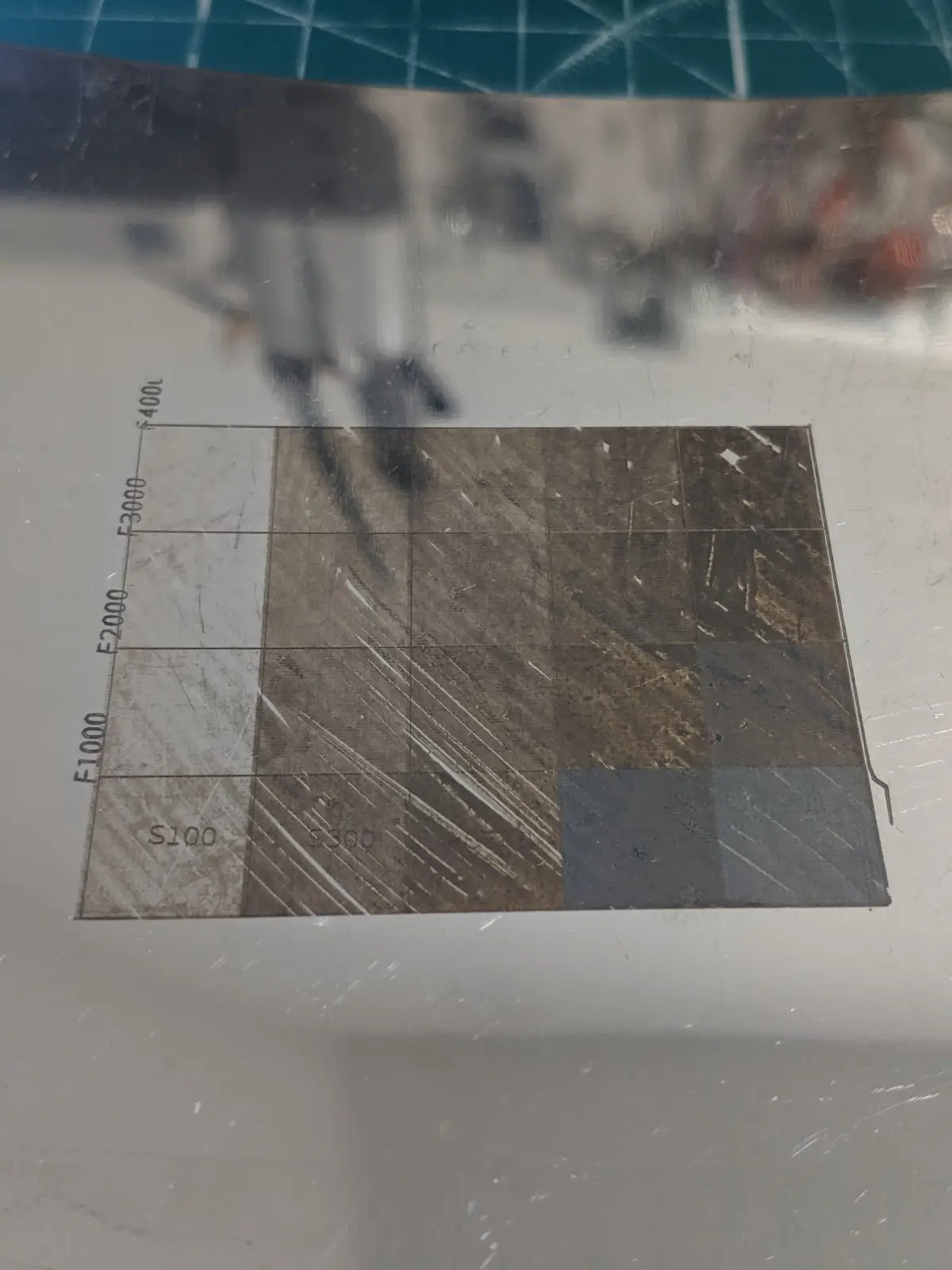

First I tried to engrave a test pattern, generated in LaserGRBL, with speeds 1000-4000 mm/min and powers from 10% to 90%. Internets say a necessary step is to paint the surface with black marker, which is what I did. It is done on a random piece of metal, and it’s clearly visible that the metal deformed under the laser. The bottom side has faint contours of engraving, including hairline lines that laser drew between the pattern rectangles.

Yan can do some magic of multi-colored engraving by varying speed and power, but in my case the "multi-colored" part is a big stretch of the term. While you can tell maybe 2 or 3 shades apart, it’s more like "brownish" and "slightly darker brownish", not blueish that some pictures advertise.

The laser head moved the piece at the end, so the labels are misaligned. First attempt at dog tag was also moved by the head (of by the airflow, not sure). In general I find the head securing system to be inadequate, and the gap between the head and the surface being engraved is close to non-existent, so the head often touches and moves the stock.

The dog tag itself is ~2 mm thick and very shiny. I designed the image in LibreOffice Draw. I also tried Inkscape, but found the text tool to be rather uncomfortable. LibreOffice is at least somewhat compatible to MS Office workflow. I wanted to do it in a vector software, but since I ended up exporting to PNG, raster tools like Photoshop should also have worked.

LaserGRBL can import PNGs, process them into B/W images and turn them into engraving jobs. There is even a database of speed/power settings that I ended up not using (since I already did a test pattern, I knew what settings I needed).

Immediately after engraving, the metal piece is rather hot, but not uncomfortably so.

Aligning the piece and the laser is a thing I’ll need to solve. While educated eyeballing worked for one side of the tag, it totally failed for the other.

The laser itself has a MKS LS ESP32 Pro, which has an ESP32-S3 SoC as brains and is WiFi capable. The firmware is a fork of Grbl-ESP32 with unpublished source. The WebUI is not particularly user-friendly and powerful, and whether the firmware accepts G-code over sockets is unclear.

I plan to replace the firmware with FluidNC, an continuation of Grbl for ESP32, which is open-source and much better documented.