Silicone casting journey, part 2

For the past couple months I’ve been diving deeper into silicone casting. Here is what I’ve achieved so far.

Switch from platinum-based silicone to a tin-based one

Cheap platinum-based silicone from aliexpress that I bought for experiments was very bad. Even when it cured properly, it still felt too gooey and sticky to be used for tyre models. It also had severe inhibition problems with Anycubic Std resin, which should be an issue for all platinum silicones. I’ve since bought SirayaTech Fast Navy Grey resin, which is said to have different photo-initiator that does not inhibit silicone, but since the silicone has other problems, I decided to buy different silicone anyway.

To avoid inhibition problems altogether, I chose to go with tin-based silicone this time, and buy it somewhere specialized (i.e. not aliexpress).

Admittedly, it was more difficult to find, but there are options from formx.nl, siliconesandmore.nl and some Reshimica products (Italian) on Amazon. I bought 500ml bottle from siliconesandmore.nl (hardness 35A) along with smallest bottle of hardener, which they sell separately. Mixing ration for tin silicone is around 100:5, which is drastically different from platinum ones (usually 1:1), so for small amounts of silicone you need really precise scales to measure drops of hardener. I plan to make a table of how many drops go well for what amount of silicone.

Unsurprisingly, the silicone turned out to be much better than noname aliexpress one. Indeed it is not inhibited by resin 3D prints (both from old Anycubic resin and SirayaTech Fast one), solidifies into hard but flexible material.

Coloring silicone

By default tin-based silicone is milky white. There are some dedicated colorants for silicones, but before buying those I tried what I had available first.

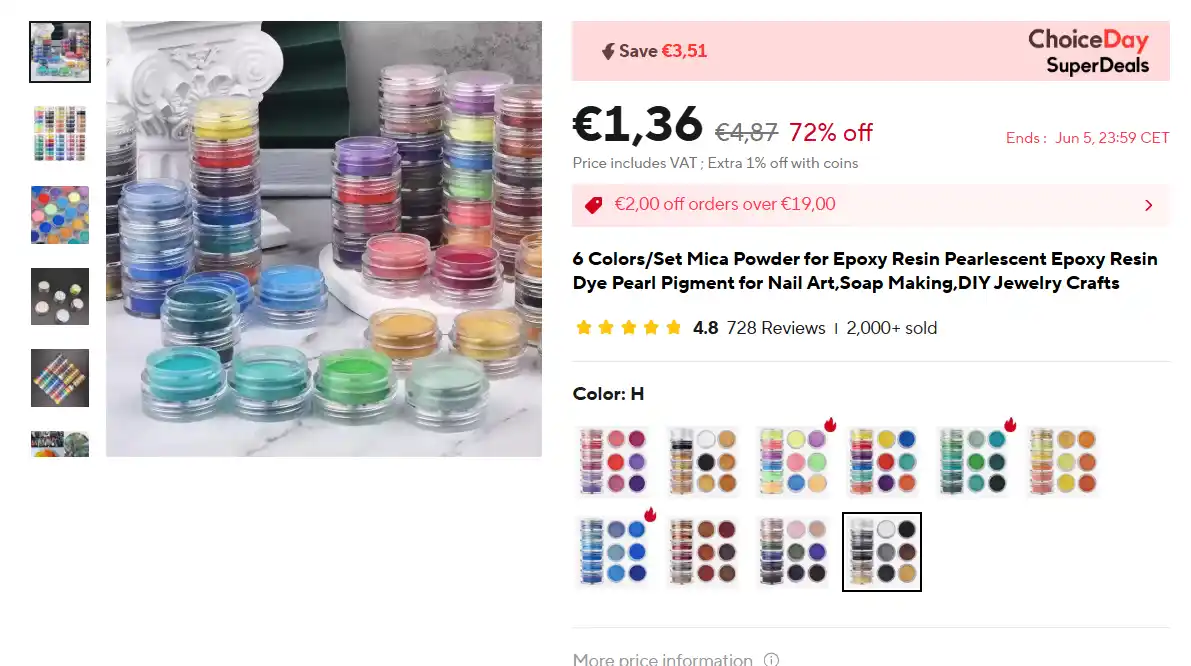

Mica powder. Used in nail polishing and other beauty applications, is very cheap and readily available on aliexpress in dozens of colors (though most of the time it’s sparkling or pearl shade). It seems it needs a lot of powder to turn white silicone black, I only got a result that was light grey.

Oil paints used by painters. Available in craft stores, I bought a set from Action discount store. Black paint seems to color the result pretty well, the blackest result I got was from these paints. It needs to be checked if oil paint affects the hardness of the result, as what I got was noticeably softer than unpainted silicone. But that could be due to variations in hardener mixing ratio.

Liquid pigment for epoxy. Used in epoxy art, cheap and available on aliexpress in lots of colors. Presumably contains pigment in high concentrations, as small drops are enough to give tint to huge amounts of epoxy. Yet to be tested.

It will be interesting to also try acrylic model paints, as modellers tend to have them in abundance.

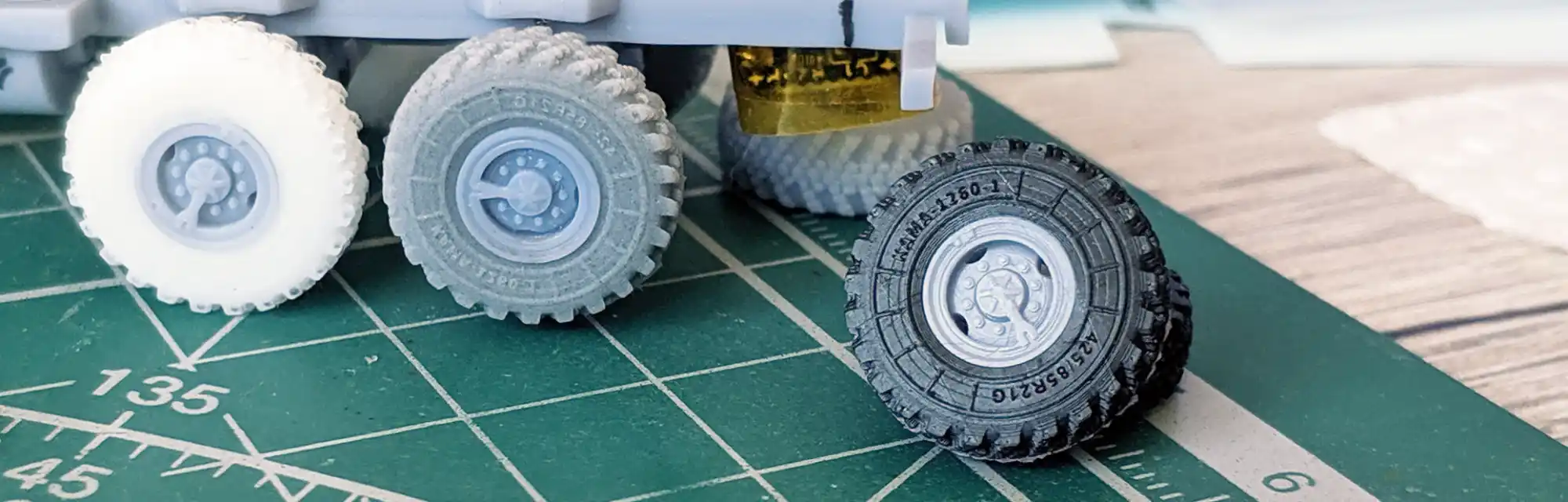

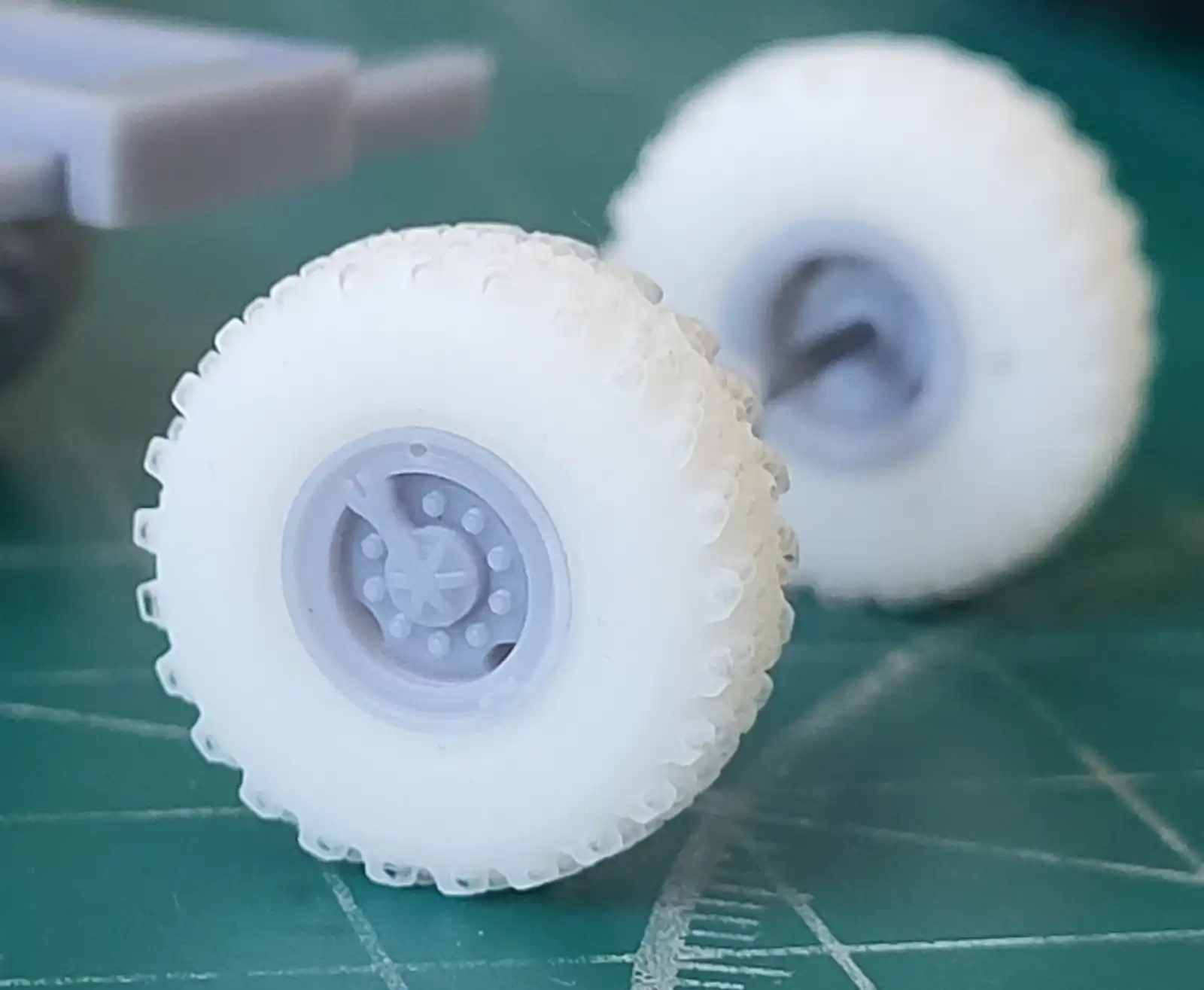

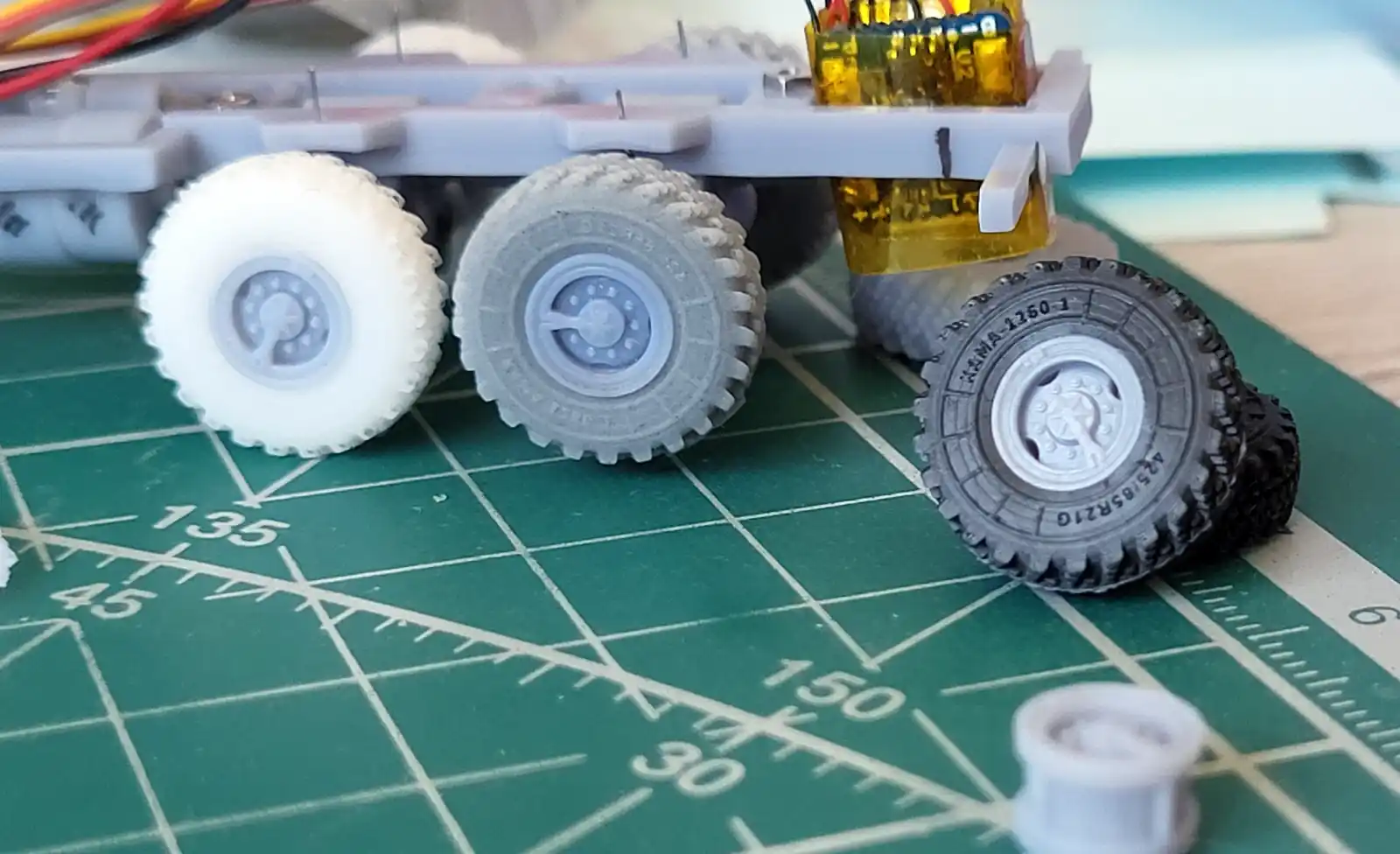

Started to get usable results

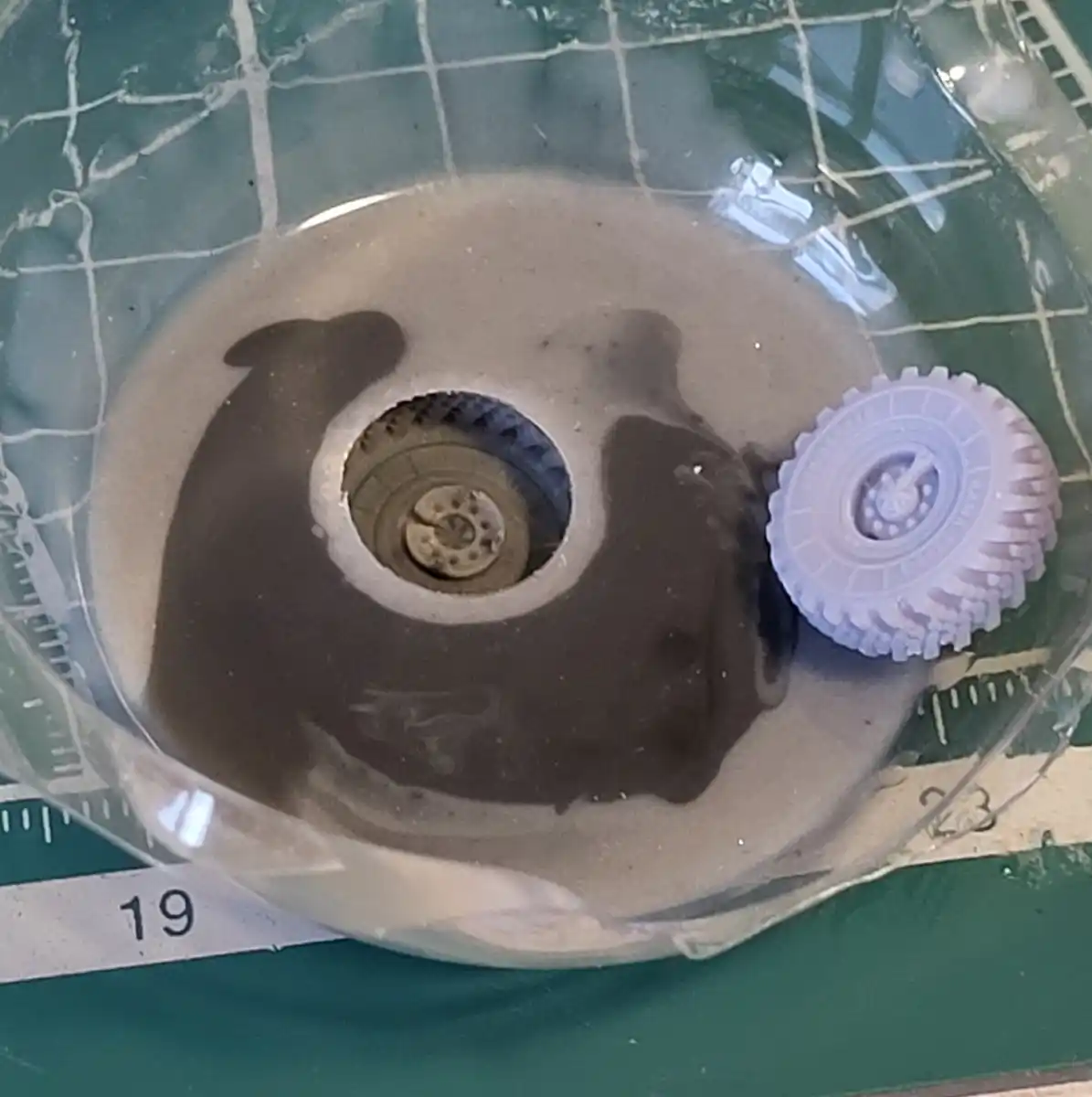

I made some molds for offroad tyres, currently on 3rd iteration. The latest one is a 3-part mold for casting front tyre that is almost empty inside, so needs special part for internal volume.

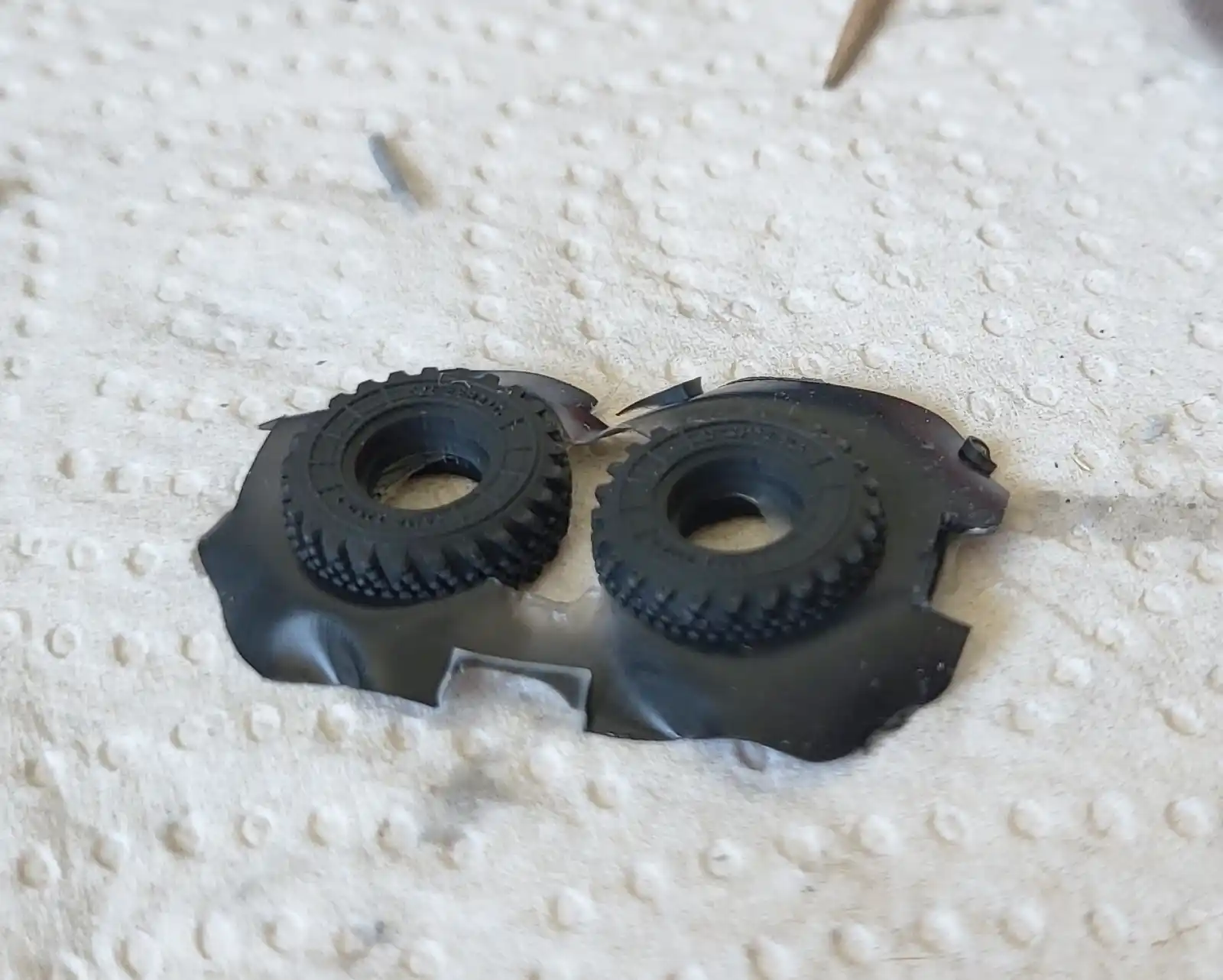

With tin-based silicone and colorants I finally got some results that can be used on the model.

Molds for casting other materials

Another usage of silicone is making molds to pour other materials that solidify. For now I’ve only tried epoxy, UV-curable resin and, out of curiosity, solder[1].

This way you don’t need to design a mold in CAD, but print the part you want to cast, make a "negative" silicone mold of it, then pour some other substance into the mold and let it cure.

This should be particular useful for non-flat glass panes on vehicles, that’s why my experiments are mostly about transparent materials.

| UV-curable resin does not work that well, as UV light does not get into silicone. So it cures in places directly lit by UV flash, but remains uncured underneath, which makes the overall result a failure. Not recommended. |

| Common quick household epoxy gives yellow-ish tint after hardening. Not recommended. |

| LEGO bricks are quite useful to build a frame for silicone casting. Silicone does not stick to it (or anything), so LEGOs are not damaged in any way. |

The next thing to try is specialized epoxy that is specifically created to give pure transparent result. It is readily available on aliexpress.