On functional models of foldable cranes

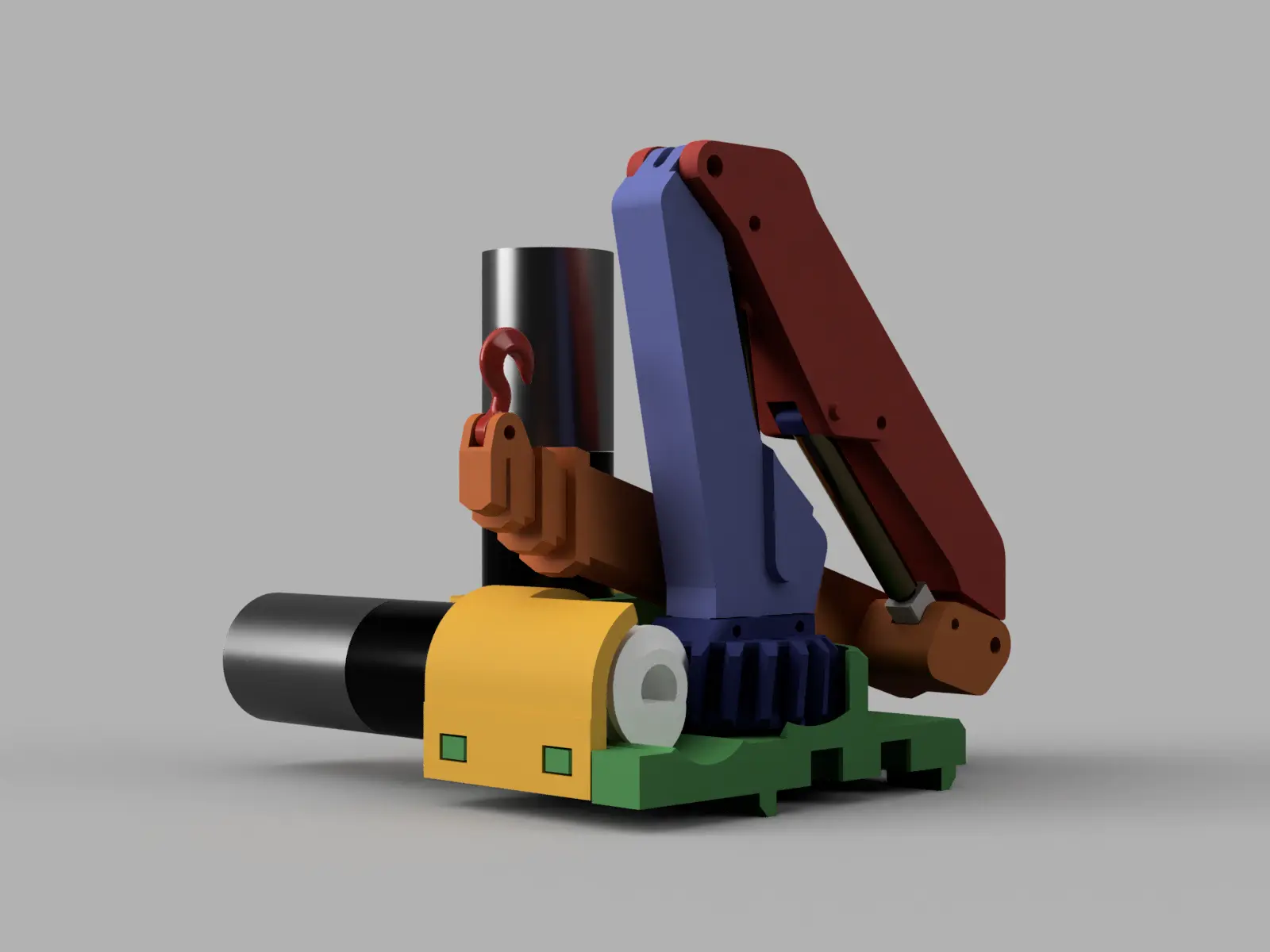

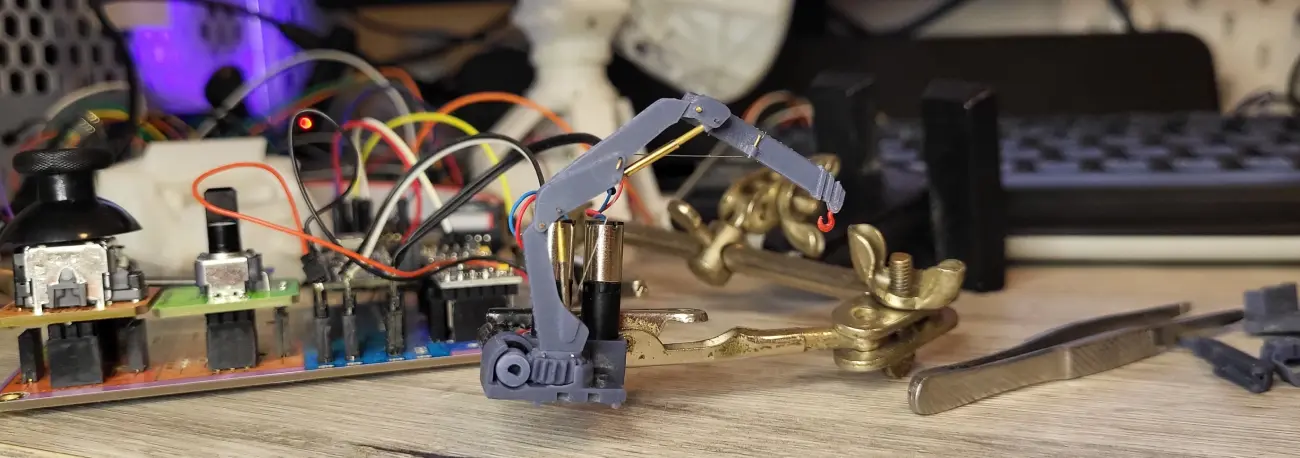

Second project I tried in the area of motorized cars was a foldable truck-mounted-crane. That’s the project that fascinated me the most out of all the videos I watched on youtube, due to it being very small and still packing aa lot of motorized functions.

I started builing my own with 3 motorized functions, crane rotation and 2 booms. Real things can also extend/retract the last section, maybe I’ll revisit this project at some later time.

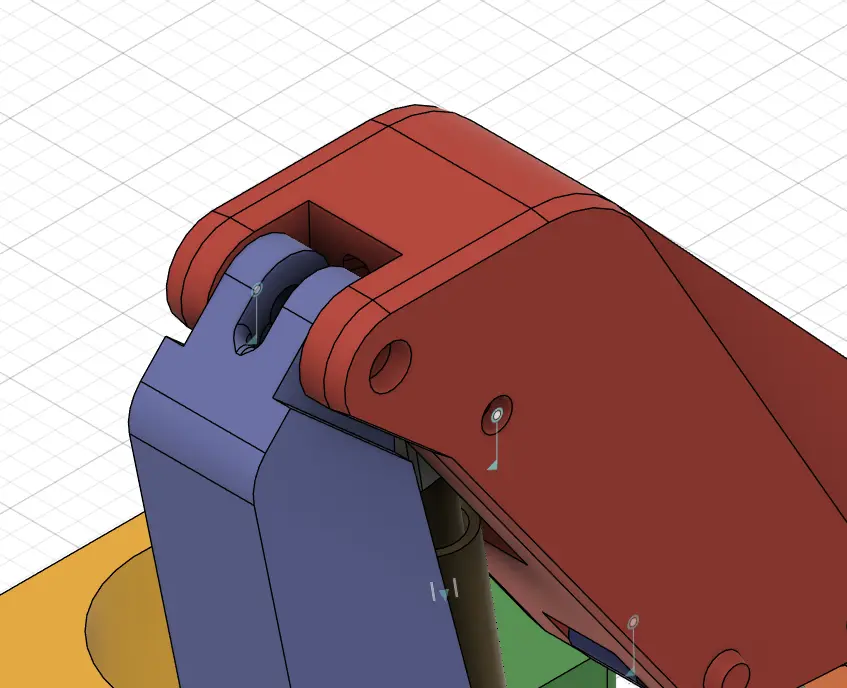

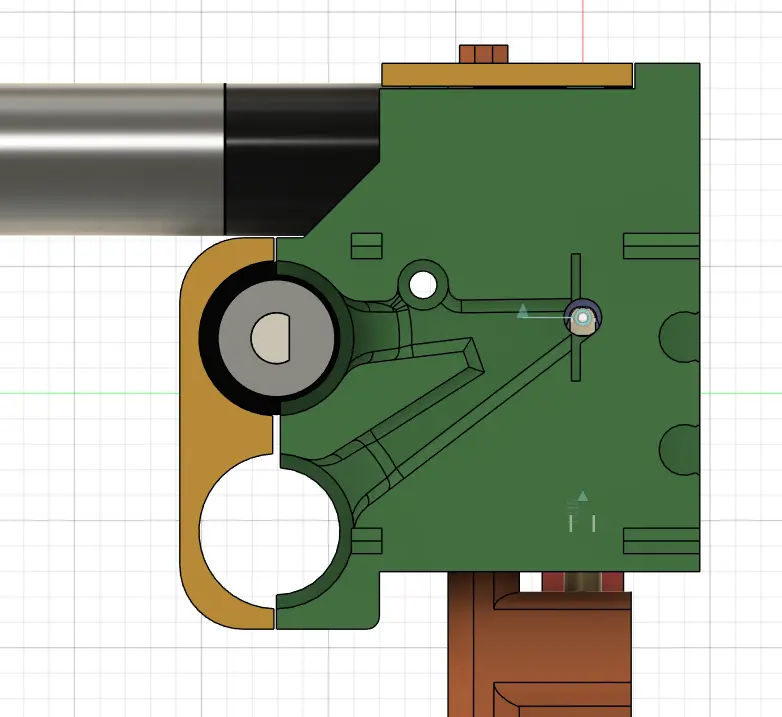

The base rotation part didn’t change a lot as it’s a rather straightforward worm drive and a bearing with lines going through center hole. Boom elevation, however, required a lot of attempts to solve and took a year in total.

Mk1 (2nd half of 2024)

First version had 2 lines going to each joint, one to raise and one to lower. Both lines were connected to one drum in opposite directions.

Pros:

-

Only 3D-printed parts required, in addition to fishing line and pins.

-

Lines are hidden inside the construction.

Cons:

-

Due to little leverage, a lot of force on the line is needed.

-

For the same reason, very little travel of line causes full swing of the joint. All this causes motor control to be jerky. At low PWM there is not enough torque, and at some point crane springs into motion and goes the half the range.

-

Complex assembly - the length of wires needs to be tuned when assembling, they cannot be tightened later with motor as tightening one wire makes another loose.

Mk2 (1st half of 2025)

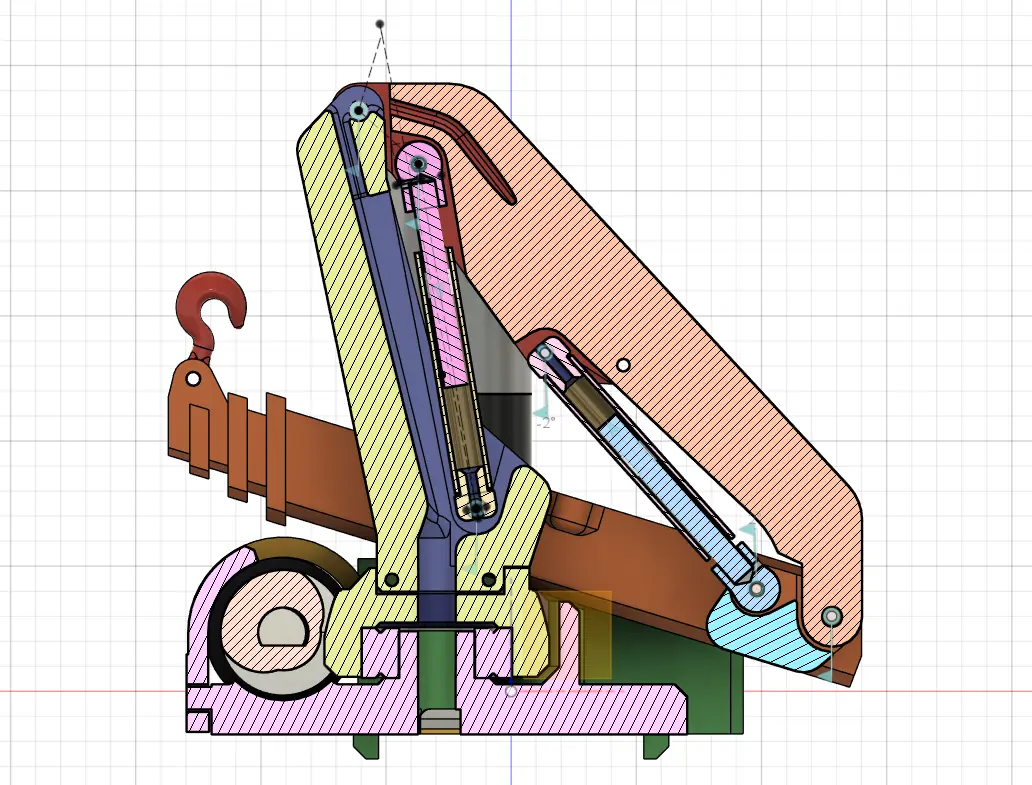

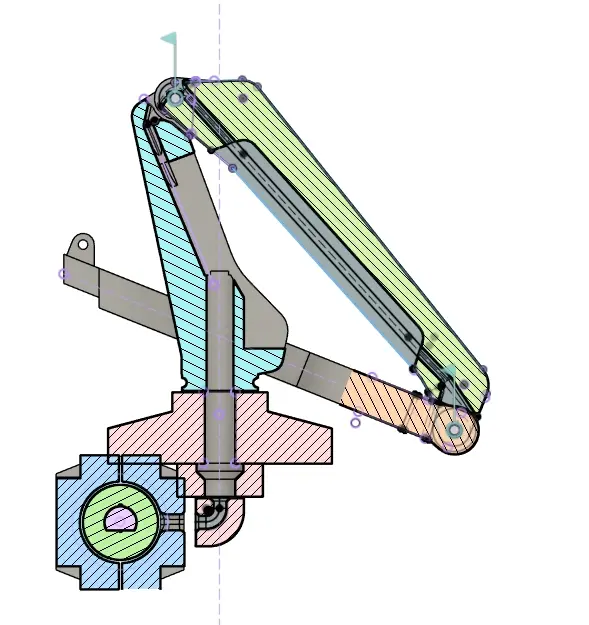

So I switched to a second version that had a spring-based piston to raise the booms and a line to reel it back.

The 3D model also has redesigned boom geometry and has realistic retracted end boom (it does not actually retract).

Pros:

-

Simpler assembly: a line can be simply attached to the drum, and can be tightened later by the moving the motor.

-

Bigger leverage for motor forces leads to precise control of movement.

Cons:

-

Difficult requirements for the piston - it needs to be short as pissible in compressed state and long as possible in extended state. The spring has a fixed extension coefficient (ratio of compressed and extended length), which puts limitations on possible lengths of the piston. Moreover, to improve lifting capacity, a thicker spring is needed, which causes the extension coefficient to be smaller. After testing several springs from pogo pins, I haven’t found a spring that satisfies the requirements.

-

Lifting power only depends on spring and not motor.

-

Some parts of lines are outside and are visible.

Mk3 (2nd half 2025)

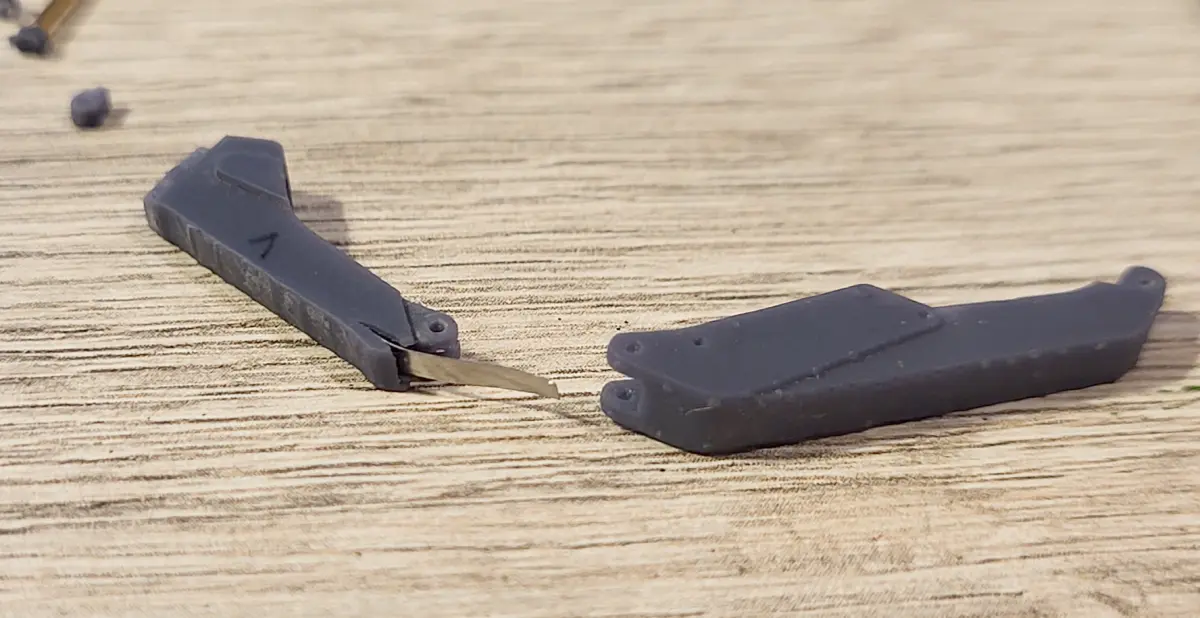

In an attempt to solve these problems, I tried a third version, which replaced piston with a sheet of spring steel to lift the booms (and a line was still used to reel it back).

Pros:

-

No limitations of the piston length.

Cons:

-

Due to little leverage, large force is needed from the metal sheet to lift the boom, which caused its resin housing to break over time.

-

Lifting power is determined by metal sheet, not motor power

-

304 steel that I used has plastic (not elastic) deformations in sharp bends, so a large bend is needed, this makes sheet ends slide on every motion, which damages resin over time and makes the sheet stuck

-

Sheet is very visible and unrealistic.

-

Lines are visible as well.

| 304 steel has better springiness than 301. It’s also more difficult to find and is slightly more expensive. |

Back to Mk2 with 2-stage piston

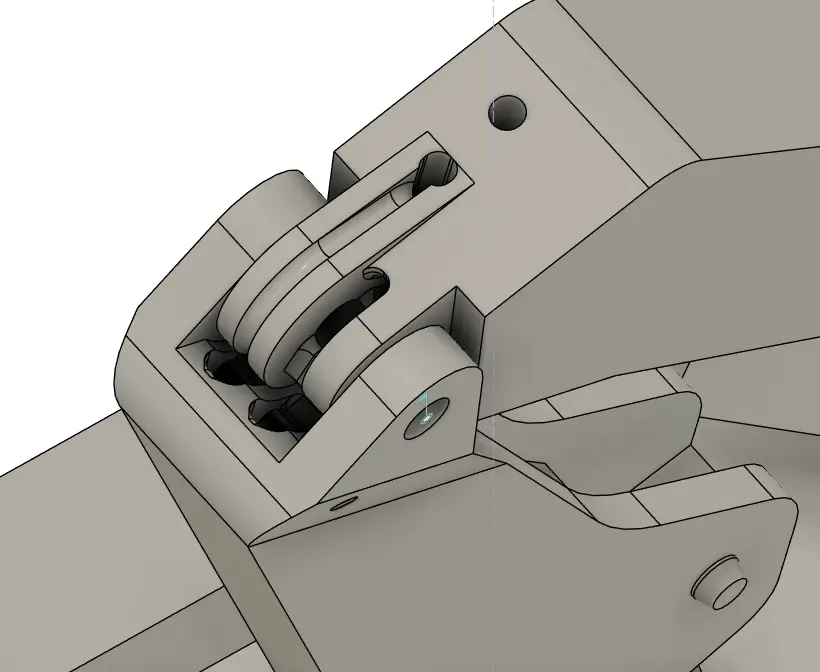

So I deemed Mk3 unfeasible and revisited Mk2 solution. As there are differently sized pogo pins (labelled P100, P75 and P50), it’s possible to put one smaller piston inside the rod of a larger one, increasing its extension coefficient. The piston is now rather fragile and complex to assemble, but on the other hand, because there are 2 springs now, pistons do not need to extend to their extreme positions, so the design is more tolerant to inaccuracies in lengths of cuts of copper tubes. Having 2 springs in the same place where there was previously one, increases lifting force to sufficient level even if one of the springs is os smaller diameter.

The lines are still visible, this is a disadvantage the project will have to live with. Most likely it will not be noticable during actual operation.